Kidderminster

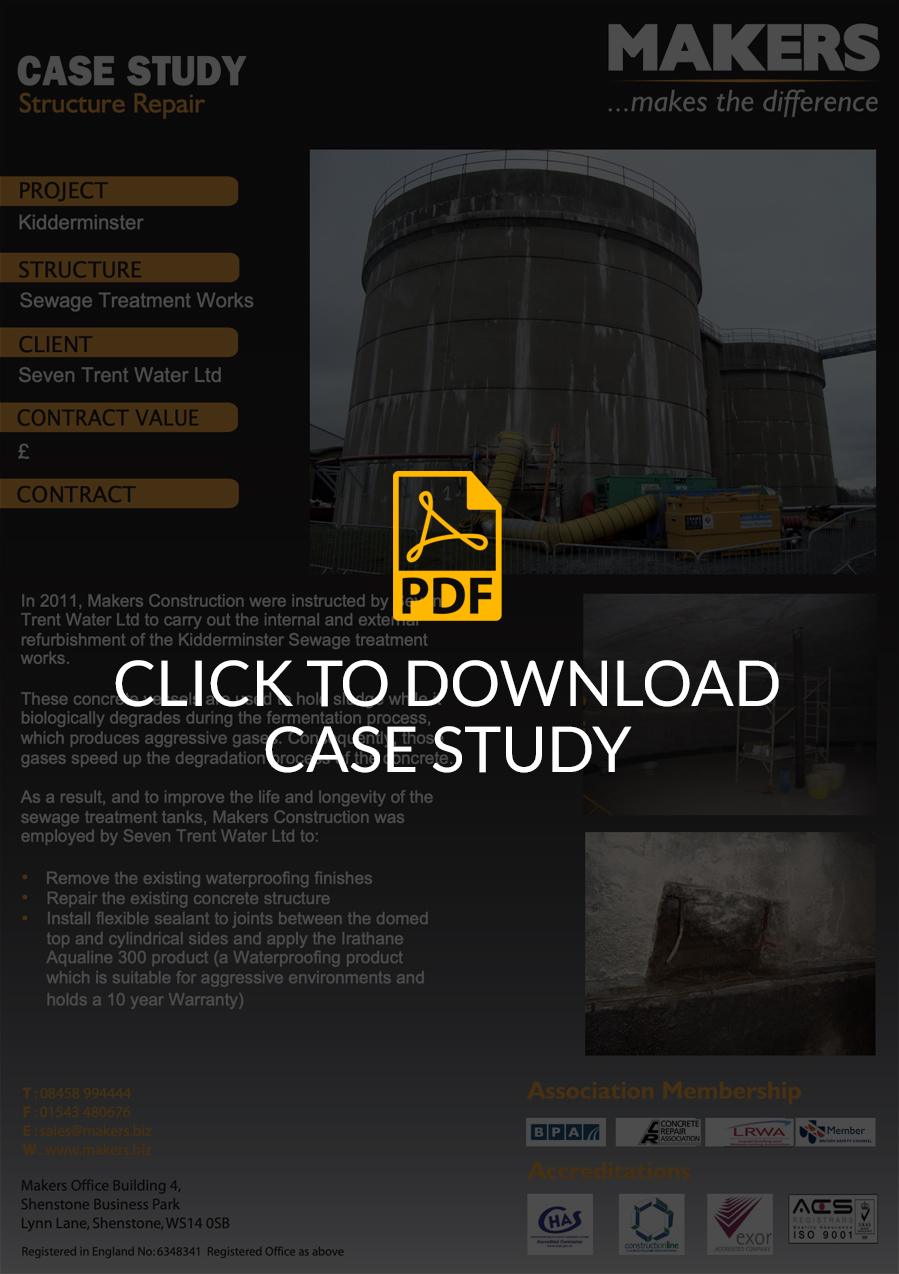

In 2011, Makers Construction were instructed by Seven Trent Water Ltd to carry out the internal and external refurbishment of the Kidderminster Sewage treatment works.

These concrete vessels are used to hold sludge while it biologically degrades during the fermentation process, which produces aggressive gases. Consequently, those gases speed up the degradation process of the concrete.

As a result, and to improve the life and longevity of the sewage treatment tanks, Makers Construction was employed by Seven Trent Water Ltd to:

- Remove the existing waterproofing finishes

- Repair the existing concrete structure

- Install flexible sealant to joints between the domed top and cylindrical sides and apply the Irathane Aqualine 300 product (a Waterproofing product which is suitable for aggressive environments and holds a 10 year Warranty)

See the .pdf for the full Structural Refurbishment Case Study…

Call us on 0845 899 4444 or email sales@makers.biz